Iceotope has published a new study with Meta confirming the practicality, efficiency and effectiveness of chassis-level liquid cooling technology to meet the cooling requirements of high-density storage disks increasingly being deployed and utilised by hyperscale data centre service providers.

The recently published study with Meta suggests the advantages of improved thermal management, reduced vibration, and equalised temperature across the JBOD, which leads directly to lower failure rates and costs for data centre operators. The hard drive systems supplied in a rack form factor in chassis drawers are an ideal fit for precision immersion cooling technology.

Neil Edmunds, Director of Innovation, Iceotope, said: “As demand for data storage continues to escalate, so will the solutions needed by hyperscale data centre providers to efficiently cool the equipment. The study demonstrated that liquid cooling for high-density storage successfully cools the drives at a lower, more consistent temperature for fewer drive failures, lower TCO and improved ESG compliance.”

High-density storage proliferating

With constant streams of data emerging from the Internet of Things, video, artificial intelligence and more, up to 463 exabytes of data is expected to be generated by each person, each day by 2025. How data is accessed and interacted is constantly changing, causing a real impact on the processing and storage of that data. In just a few years, it's predicted that global data storage will exceed 200 zettabytes of which half will be stored in the cloud.

This presents a unique challenge for hyperscale data centre storage infrastructure. According to Seagate, cloud data centres choose mass-capacity hard disk drives (HDDs) to store 90% of their exabytes. Typically found in a 3.5-inch form factor, HDDs are tried and tested technology which continues to offer data centre operators cost-effective storage at scale. Current top-of-the-range units provide 20 TB capacity, but this is expected to reach >120TB by the end of the decade.

More data storage means more spinning disks, higher-speed motors, and more actuators – all of which translate into more power being used. As disks go up in power, so does the amount of heat they produce. The introduction of helium into hard drive enclosures over the last decade has not only improved disk performance with less drag but with the units now sealed, the practicality of using liquid cooling solutions at HDD level has been opened.

Meta study liquid cooling for high-density storage

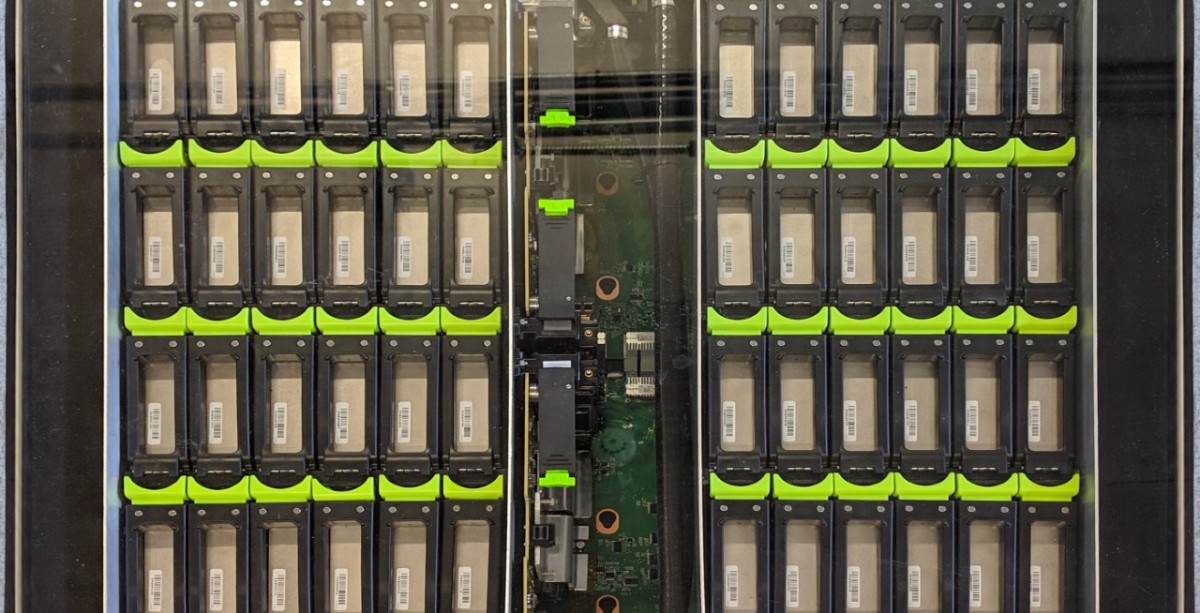

The study showcases an air-cooled, high-density storage system re-engineered to utilise single-phase immersion cooling. The standard commercial storage system consisted of seventy-two hard drives, two single socket nodes, two SAS expander cards, NIC and a power distribution board in a 4OU form factor. The hard drives were hermetically sealed, and helium filled.

The liquid cooling system tested was an Iceotope precision immersion liquid cooling system - the air-cooled version was modified with the addition of a dedicated dielectric loop connected to a liquid-to-liquid heat exchanger and pump. Meta proceeded to measure temperature variation across the hard drives and cooling pump power in the air-cooled and liquid-cooled systems.

The results are conclusive

The study successfully demonstrated precision immersion cooling was a more efficient means of cooling the HDD racks with the following results:

• Using precision immersion liquid cooling, the variance in temperature between all 72 HDDs was just 3°C, regardless of location inside the JBODs

• Liquid cooling demonstrated that the HDD systems could operate reliably in rack water inlet temperatures up to 40°C.

• System-level cooling power was less than five percent of the total power consumption.

• Liquid cooling’s virtually silent operation helps mitigate acoustic vibrational issues for drives often encountered with air-cooling solutions.

While precision immersion is found to be a superior alternative to air-cooling high-density disk arrays, other forms of liquid cooling including cold plates, tank immersion, or two-phase immersion, don’t preserve the operational benefits such as HDD density, user access for serviceability and ability to hot swap drives to the same degree.